Quality

Certified

Rely on reproducible quality with us. We have set ourselves the task of complying with the zero-error principle, as well as to achieve 100% delivery reliability. Our TÜV-Süd certified quality management system, to DIN EN ISO 9001, provides a guarantee for our system’s high-quality.

Quality is our mantra

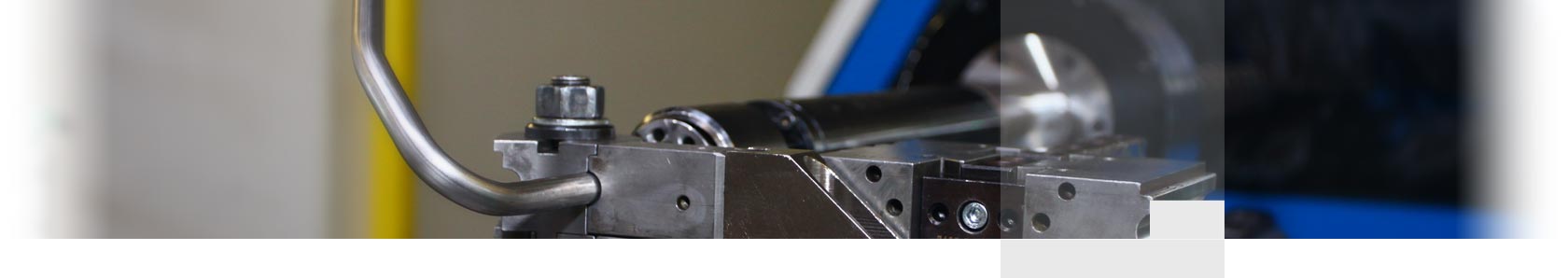

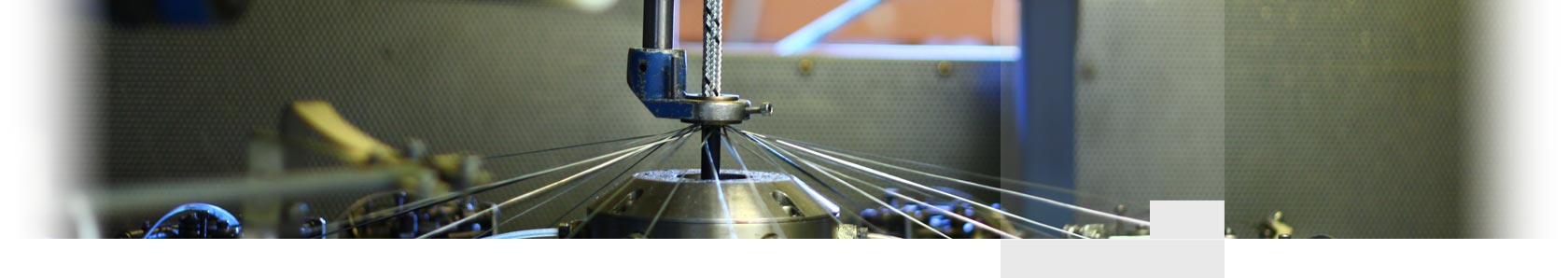

We have a state-of-the-art testing and measuring room with sophisticated coordinate measuring machines for the assurance of your individual requirements and to produce initial sample inspection reports.

State-of-the-art measuring methods

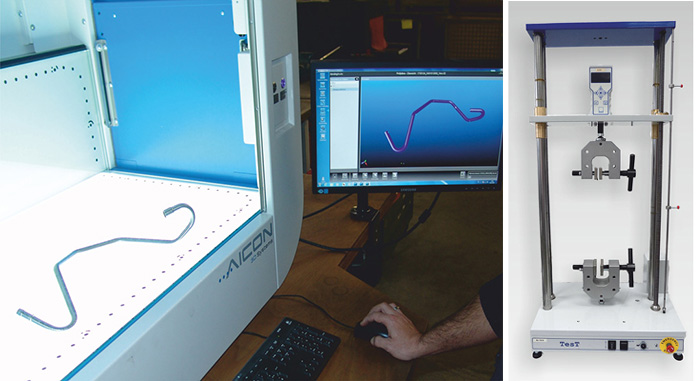

We focus on pioneering technologies with our 3D measuring cabin. Equipped with LED lighting technology and 8 high-resolution cameras, the highest measuring accuracy is achieved (measuring accuracy of 0.035 mm).

Measurements can be taken to determine the pull-off force to demonstrate safe connections between the hose and connection fittings.

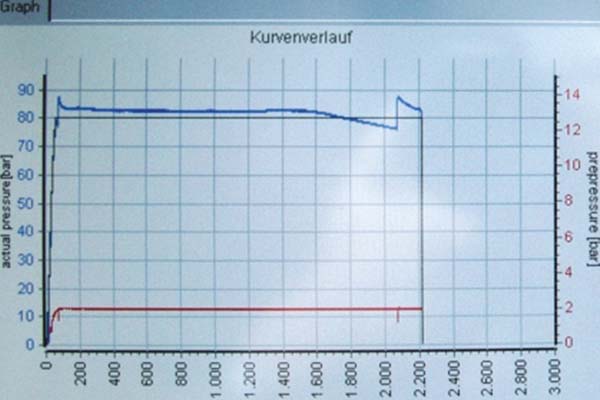

Pressure and sealing tests

We also carry out extensive pressure and sealing tests with all media, water or air (e.g. leakage tests) on all pipes, hoses and hose-pipe combinations on customer request. Measuring reports, for example on bursting pressure or holding pressure behaviour, can be exported directly into a file format by our testing equipment.

In the corrugated tube packing sector, we carry out a leakage test with air under water for every workpiece fitted with welded connections. In the end, you will receive a quality product from WEPF that lives up to its billing.

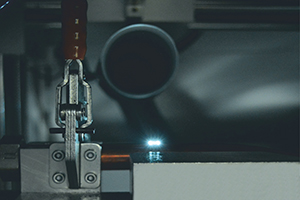

Laser marking

Do you want your items to be permanently marked for batch traceability or individual component recognition using laser marking?

With our powerful labelling laser, item numbers, verification codes, company logos, consecutive numbering or current code standards, such as QR or bar codes, can be precisely and consistently applied to a variety of materials. Therefore, we offer you the opportunity to permanently mark your components to your individual specifications and thereby achieve clear traceability for your manufactured parts.

- Item number?

- Corporate logo?

- Data matrix code?

- Confirmation of a leakage test being carried out?

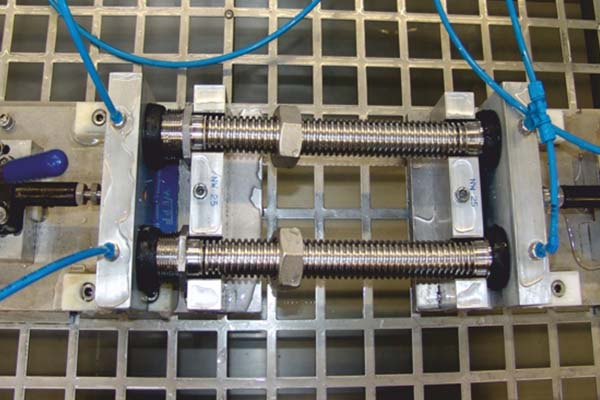

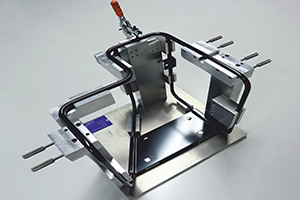

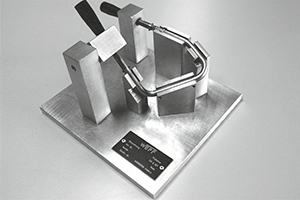

Test gauges and fixtures

Test gauges used alongside production operations enables a fast and cost-efficient 100% inspection of your series production parts. The required test gauges and fixtures are made in our in-house tool manufacturing facility.

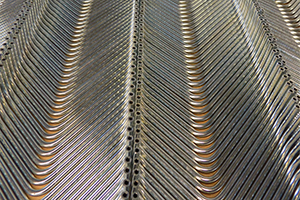

QUALITY MADE VISIBLE

Each workpiece we braze is subjected to a 100% visual inspection. In addition, we are able to respond to specific customer requirements and, for example, perform leakage tightness tests with air under water or leak tests. The preparation of micrographs as well as corresponding analyzes of brazing results achieved are also possible.