BRAZING / ANNEALING TECHNOLOGY

FLEXIBILITY AND SPEED

Our in-house soldering technology enables us to respond to your requirements even faster and more flexibly. Delivery times for the finished assemblies from the wide range of WEPF hose-pipe technology are kept to a minimum by a manufacturing process that is designed to be as economical as possible.

We are happy to offer you professional and cost-effective item soldering or annealing. Of course, we also carry out the necessary pre-assembly of individual components in a reliable manner.

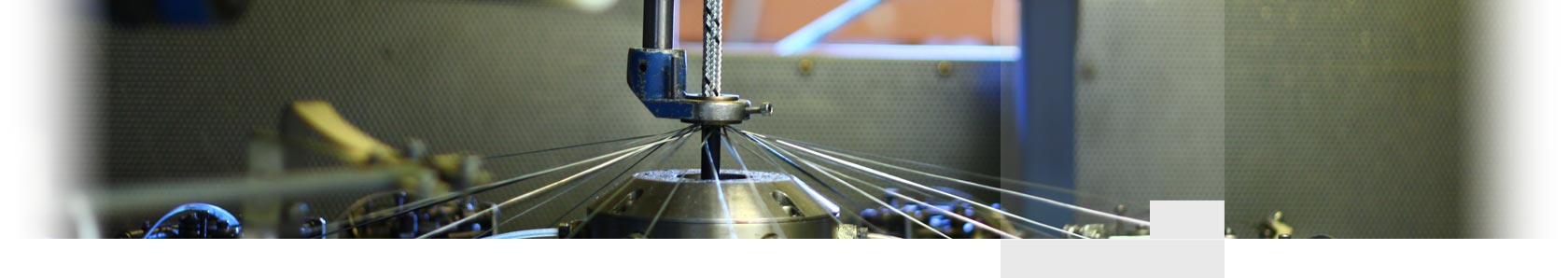

OVEN PASSAGE 250 x 250 mm

In our hydrogen continuous brazing furnace, we braze and anneal steel and stainless steel parts under a protective gas atmosphere (hydrogen-nitrogen mixture). Fast, process-safe and at a fair price-performance ratio.

The right amount does the job

The exact amount of solder required, is applied to the desired soldering locations using an electro-pneumatic metering device again and again at a consistent quality.

Accurately adjusted

Depending on the material, solder and the article-specific mass, we solder various components individually and with a computer-controlled device at the appropriate temperatures.

Our standard solders

- Copper solder ring

- Copper solder paste

- Nickel paste in different compositions

Additional solders are available on request anytime.