PIPE END PROCESSING

All’s well that ends well…

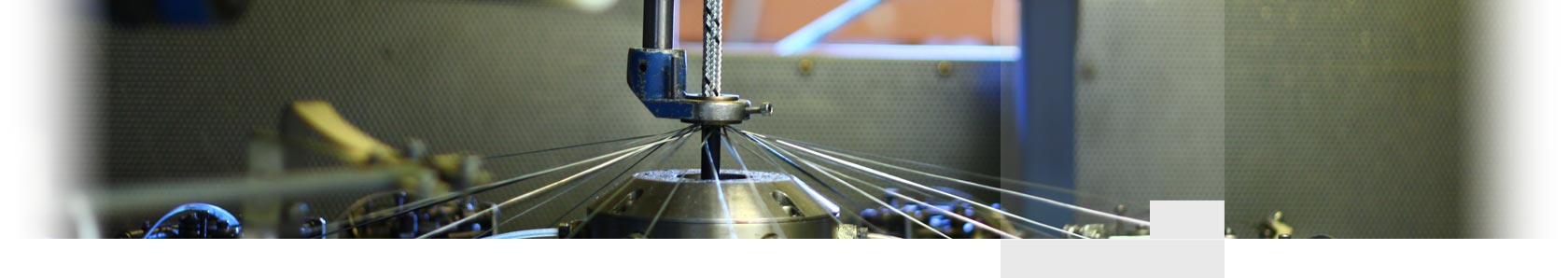

Widening, pulling in, flaring, flanging to DIN or compressing sealing cones and beads are just a few examples of our manufacturing processes in the field of pipe-end machining. These cold-forming techniques are used for pipes with an external diameter of 4-60 mm.

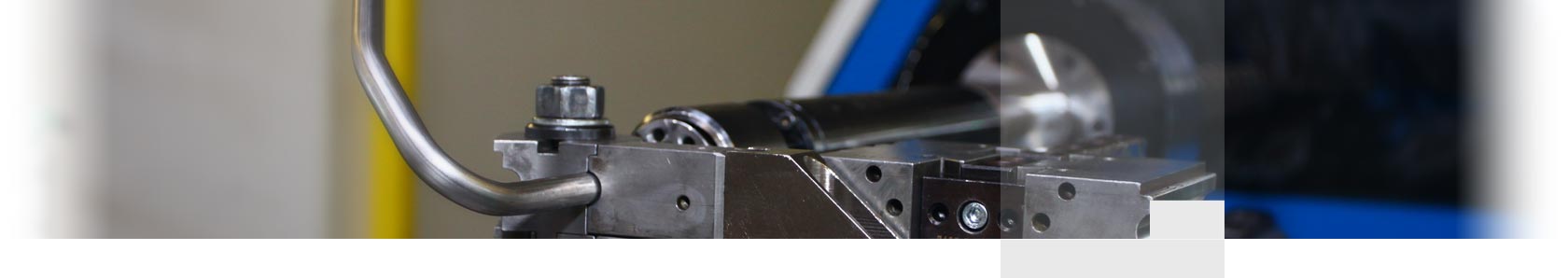

Rolling

Another option for pipe-end machining is rolling. By using this manufacturing process, more expensive joining techniques such as, for example soldering or welding turned parts, are excluded.

|

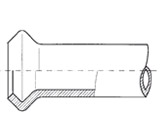

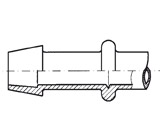

Double crimp ("E" crimp) |

|

Single crimp ("D" crimp) |

|

External crimp ("F" crimp) |

|

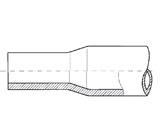

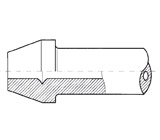

Drawing in of pipe ends |

|

Flaring of pip ends |

|

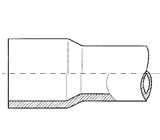

Compressing conical seal |

|

Compressing conical seal |

|

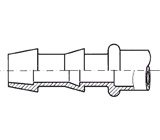

"Single" compression of hose fitting |

|

"Double" compression of hose fitting |

|

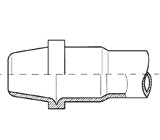

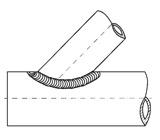

Gas-shielded welding |

|

Bead for O-ring seal |

|

Collar forming for hard soldering |